1. Product quality inspection

Use a more intelligent vision system to detect damaged products, foreign matter detection, reduce the reject rate

The product may break or be damaged during the production process. Before packaging, it is critical to verify that the product is in good condition and to ensure consistency in size, shape, color and texture to ensure customer satisfaction.

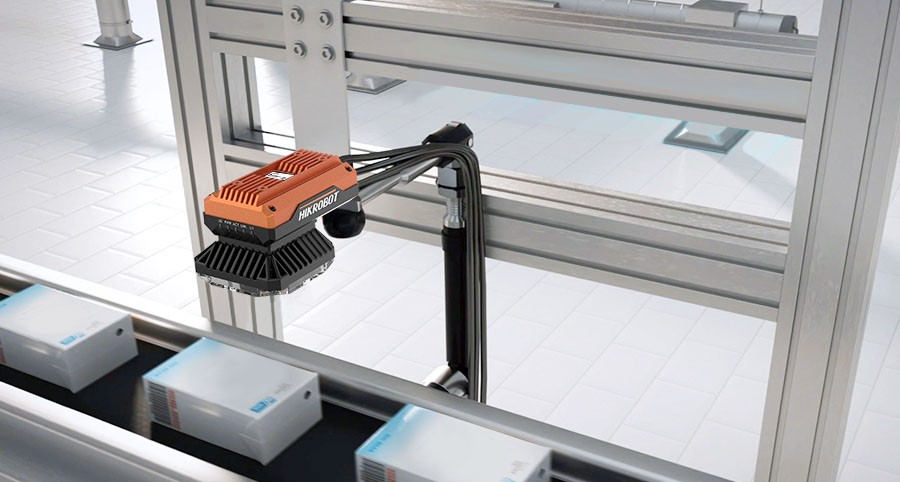

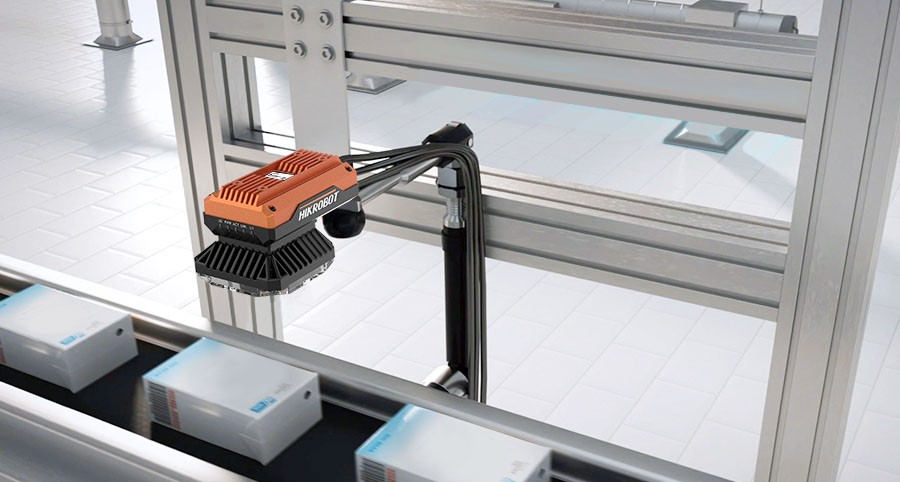

2. Package Inspection and assembly verification

Avoid unsightly or damaged packaging, improve the speed and accuracy of Assembly

Packaging will affect the consumer's perception of product quality, safety and value. The HIKROBOT vision system inspects food packaging to ensure that it is properly assembled, defect-free and complete. Early identification of assembly defects can save a lot of time and cost, especially if a single defect can affect a whole batch of products. Vision-guided quality checks ensure integrity and consistency, while robotic pick-and-place functions speed the transition from production to packaging and prevent errors。

3. Product management traceability

Avoid unsightly or damaged packaging, improve the speed and accuracy of Assembly

Regulators in China and other parts of the world require manufacturers to label and track common food problems, manufacturers must be able to quickly identify and locate problematic products in the supply chain that could harm consumers. The vision system and image reader have a good read rate, which can greatly improve the speed, accuracy and productivity of the warehouse and distribution center. It can process batches of products quickly, easily and accurately, read printed or covered code on reflective materials, and track products throughout the supply chain to avoid counterfeit products.