1. Positioning boot

The position information of the measured object is obtained by the machine vision technology, and the robot is guided to perform a series of operations.

Based on image calibration, object detection, size search and other algorithms, the main role in robot guidance-related applications is to accurately obtain the coordinates and angles of objects (grasping objects) and objects (to be assembled objects) , the image coordinates are converted into robot coordinates that can be recognized by the robot to guide the robot to locate and assemble.

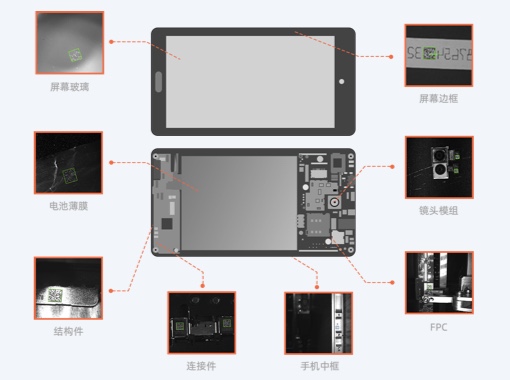

2. Code system identification

The process of electronic industry is complex. In some links of industry chain, identification of product ID information is carried out.

Demand for electronic devices such as smartphones and tablets has soared. With the increasing number of parts and the accelerated development of product miniaturization, manufacturers are also committed to the pursuit of high-quality traceability management. In view of the miniaturization of electronic parts, in many cases from the traditional contact printing processing methods to use non-contact high-precision laser printing, processing. As a result, the demand for fine, high-quality, low-damage engraving traceability is increasing.

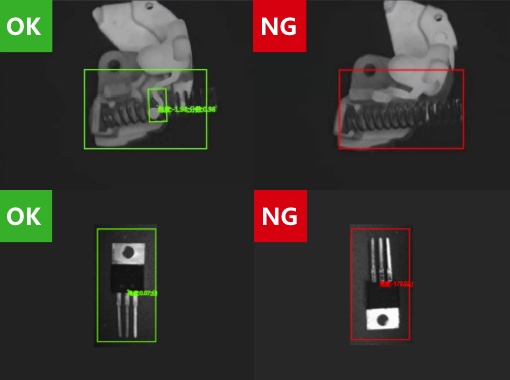

3. Defect detection

Check the surface of electronic products for scratches, damage, spots, color differences and other defects

In the process of manufacturing products in the electronic industry, defects can not be avoided, and the quality of products is increasingly demanding, so defect detection is a very important application in this industry, machine vision has the ability of high precision and high speed. It can detect many kinds of defects, such as scratch, damage, spot, color difference and so on.