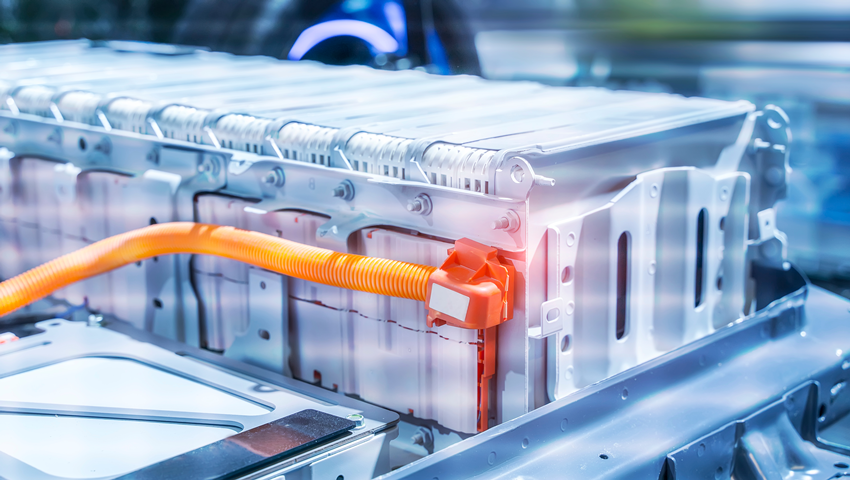

1. Visual applications for lithium-ion batteries

Includes raw material (substrate, diaphragm) testing, front-end sheet molding, middle-core equipment, to the rear of the module pack

The quality of incoming materials, such as diaphragm, substrate and so on, needs to be judged by visual aid to eliminate defective products, and the linear array is the main scheme. The front part of the battery is usually composed of a linear array camera and a plane array CCD, which is used to detect the surface defects and size information related to the polar plate. In the middle and back section of the equipment, the vision application is mainly based on the plane array CCD and 3D laser profiler, which has many requirements such as assembly positioning, assembly effect rechecking, welding and dispensing effect checking, code reading and source tracing, etc.

2. Visual applications in the photovoltaic industry

In the PV industry chain, vision is concentrated in the silicon wafer, battery, module link, upstream of the silicon downstream of the inverter application opportunities are relatively small